-

EPO/EPS/GPO Extrusion-Based Foaming Pelletizing Line

-

Continuous Granulation System for Salt-Lake Lithium Extraction Adsorbents

-

Underwater Pelletizing System (small)

-

Underwater Pelletizing System (large)

-

Underwater Strand Pelletizing System

-

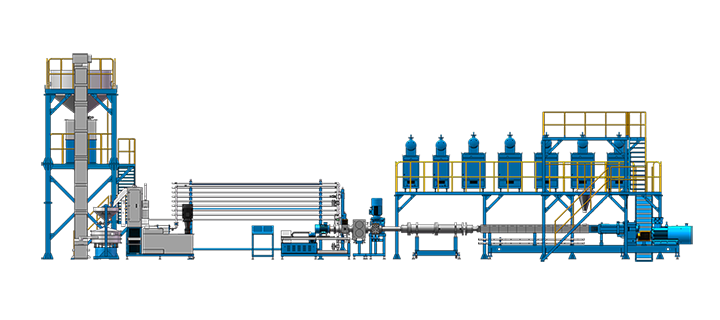

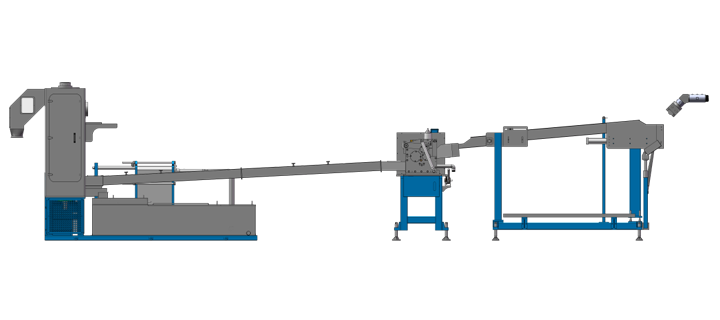

EPO/EPS/GPO Extrusion-Based Foaming Pelletizing Line

Product IntroductionSuitable for foaming pellets such as EPO, GPO, EPP, and EPS, with pellet sizes of 0.6–4.0 mm. For direct-foaming materials like EPP/ETPU, production capacity is 100–300 kg/h; for foaming-compatible materials like EPS/EPO/GPO, production capacity is 1,000–4,000 kg/h. -

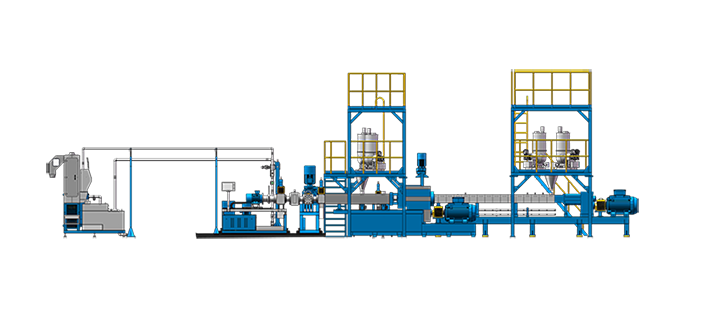

Continuous Granulation System for Salt-Lake Lithium Extraction Adsorbents

Product IntroductionOne-Step Continuous Granulation System for Salt-Lake Lithium Extraction Adsorbents, suitable for aluminum-, manganese-, and titanium-based materials. Produces uniform pellets with diameters of 0.8–1.2 mm at a capacity of 100–800 kg/h. Features include vacuum feeding, complete loss-in-weight dosing system, ultra-high-torque extruder, mold temperature controller, chiller, gear pump, screen changer, full underwater pelletizing system, and more. The system is well-configured and operates stably (customer case studies available for on-site inspection). -

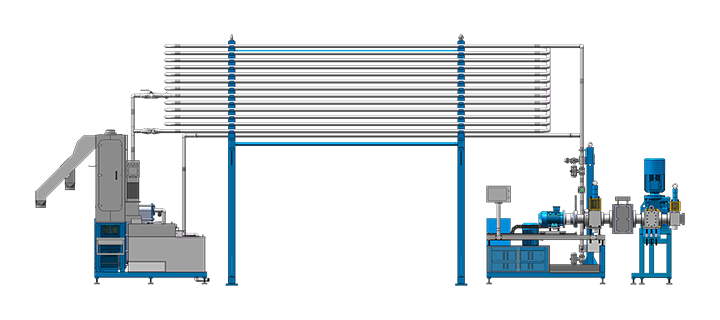

Underwater Pelletizing System (small)

Product IntroductionSuitable for all materials, with a production capacity of 200–3,000 kg/h. Equipped with pneumatic cutter, German-imported pneumatic valve core, Siemens PLC touchscreen, ABB inverter, and oversized filter tank. The system is well-configured, easy to operate, and ensures stable long-term operation. -

Underwater Pelletizing System (large)

Product IntroductionSuitable for all materials, with a production capacity of 5,000–15,000 kg/h. Equipped with hydraulic cutter, German-imported pneumatic valve core, Siemens PLC touchscreen, ABB inverter, and oversized filter tank. The system is well-configured, easy to operate, and ensures stable long-term operation. -

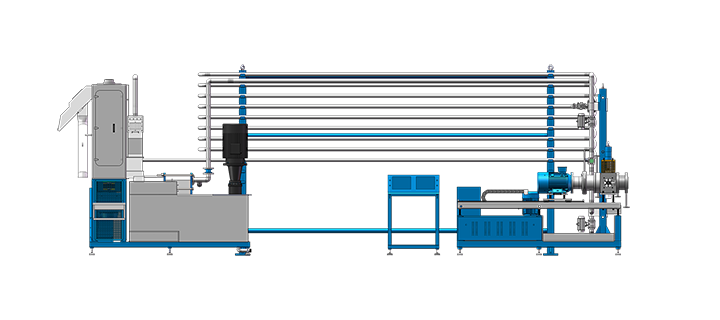

Underwater Strand Pelletizing System

Product IntroductionSuitable for PET, PC, PA, PMMA, etc., with a production capacity of 1,000–5,000 kg/h. Equipped with Siemens PLC touchscreen, ABB inverter, and Festo clamping cylinder. The system is well-configured, easy to operate, and ensures stable long-term operation.