Suitable for foaming pellets such as EPO, GPO, EPP, and EPS, with pellet sizes of 0.6–4.0 mm. For direct-foaming materials like EPP/ETPU, production capacity is 100–300 kg/h; for foaming-compatible materials like EPS/EPO/GPO, production capacity is 1,000–4,000 kg/h.

Product Introduction

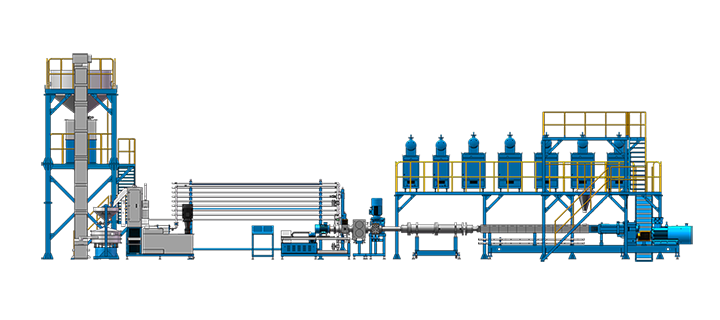

Equipment at Customer Site(Latest Model)

Suitable for foaming-compatible pellets such as EPO, GPO, EPP, and EPS, with pellet sizes of 0.6–4.0 mm. For direct-foaming materials like EPP/ETPU, production capacity is 100–300 kg/h; for foaming-compatible materials like EPS/EPO/GPO, production capacity is 1,000–4,000 kg/h. Features include vacuum feeding, complete loss-in-weight dosing system, ultra-high-torque extruder, mold temperature controller, gear pump, screen changer, full underwater pelletizing system, lifting and mixing units, and weighing & packing system. The line is well-configured and operates stably (customer case studies available for inspection).

Customer Cases

Equipment at Customer Site(Latest Model)

Specification parameters

|

Product model |

Production range |

Suitable materials |

Extruder |

Particle diameter |

|

RZW500 |

500kg/h |

EPS/EPO/GPO |

Twin-screw |

0.6-1.5 Optional |

|

RZW1000 |

1000kg/h |

EPS/EPO/GPO |

Twin-screw |

0.6-1.5 Optional |

|

RZW2000 |

2000kg/h |

EPS/EPO/GP0 |

Twin screw |

0.6-1.5 Optional |

|

RZW3000 |

3000kg/h |

EPS/EPO/GPO |

Twin-screw |

0.6-1.5 Optional |

|

RZW4000 |

4000kg/h |

EPS/EPO/GPO |

Twin-screw |

0.6-1.5 Optional |