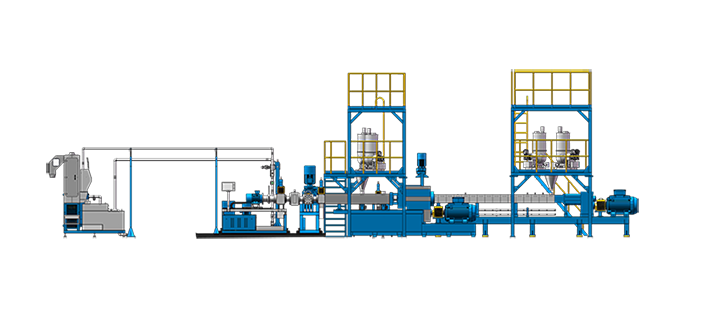

One-Step Continuous Granulation System for Salt-Lake Lithium Extraction Adsorbents, suitable for aluminum-, manganese-, and titanium-based materials. Produces uniform pellets with diameters of 0.8–1.2 mm at a capacity of 100–800 kg/h. Features include vacuum feeding, complete loss-in-weight dosing system, ultra-high-torque extruder, mold temperature controller, chiller, gear pump, screen changer, full underwater pelletizing system, and more. The system is well-configured and operates stably (customer case studies available for on-site inspection).

Product Introduction

A complete set of one-step continuous salt lake lithium extraction adsorbent equipment, suitable for aluminum, manganese, titanium, etc., with uniform particles and particle diameters between 0.8-1.2, with a production capacity of 100-800KG/H. It includes vacuum feeding, a complete set of weight loss scales, ultra-high torque main machines, mold temperature machines, chillers, gear pumps, screen changers, and a complete set of underwater particle cutting systems, with reasonable configuration and stable operation (there are case customers available for visit)

Customer Cases

Specification parameters

|

Product model |

Production range |

Suitable materials |

Extruder |

Particle diameter |

|

RZX100 |

100kg/h |

Aluminum/Manganese series |

Twin-screw+contimuous mixer |

0.8-1.2 Select |

|

RZX400 |

400kg/h |

Aluminum/Manganese series |

Twin-screw+continuous mixer |

0.8-1.2 Select |

|

RZX800 |

800kg/h |

Aluminum/Manganese series |

Twin-screw+contimuous mixer |

0.8-1.2 Select |