Expanded Polystyrene (EPS)

What Is Expanded Polystyrene (EPS)?

EPS (Expandable Polystyrene), is a styrene-based polymer produced by adsorbing or encapsulating a volatile blowing agent, such as pentane, into small bead-like pellets. After pre-expansion with steam or mold heating, the beads form numerous closed-cell foams, giving EPS its characteristics of light weight, thermal insulation, energy absorption, and ease of molding. Unexpanded EPS beads (micropellets) serve as the semi-finished material for pre-expansion and molding processes, and are widely used in construction and packaging industries.

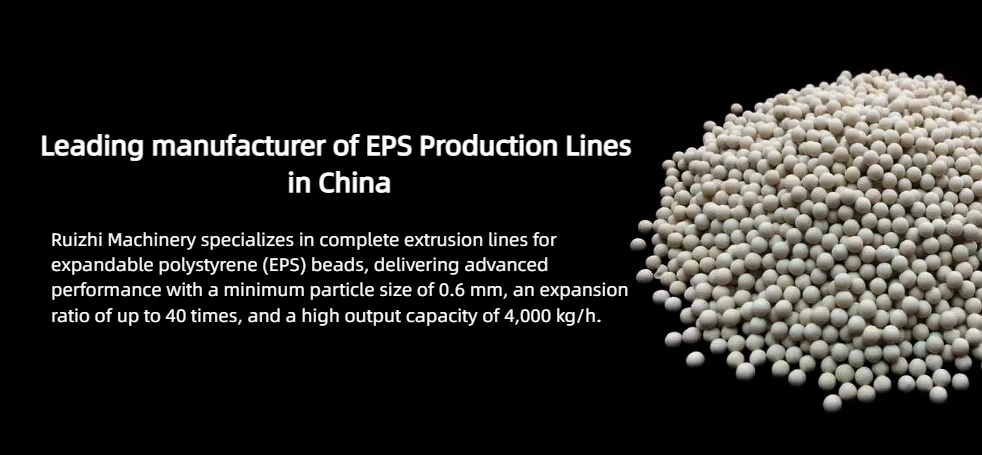

Ruizhi Machinery specializes in complete extrusion lines for expandable polystyrene (EPS) beads, delivering advanced performance with a minimum particle size of 0.6 mm, an expansion ratio of up to 40 times, and a high output capacity of 4,000 kg/h, and we offer flexible solutions tailored to customer requirements.

Ruizhi Expandable Polystyrene(EPS) production line at the customer’s site

A New Generation of Expandable Polystyrene Production Lines!

Reactive Extrusion for EPS, also known as the extrusion method, is a continuous process. Unlike traditional suspension polymerization that relies on large-scale reactors, this method integrates polymerization, blowing agent injection, and pelletizing into a single operation using an extruder.

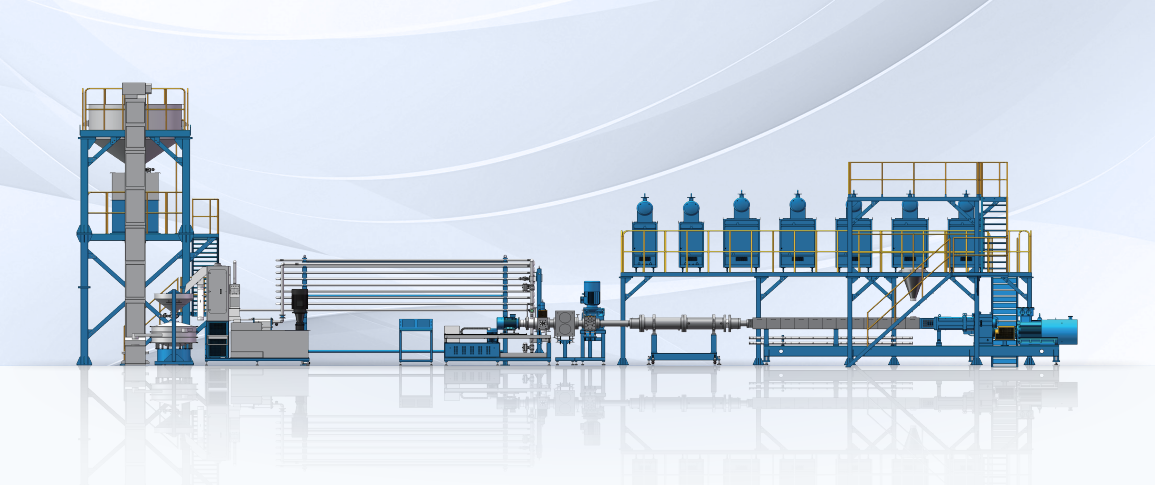

Ruizhi Machinery Reactive Extrusion Line for Expandable Polystyrene(EPS)

How EPS Beads Are Produced?

Expandable Polystyrene(EPS) Bead Production Process

- Raw Material Feeding: Styrene monomer or polystyrene resin pellets, along with additives, are fed into the extruder through a metering system (recycled material can be used)

- Melting, Reaction, and Mixing: Under the high-temperature, high-pressure conditions of the screw extruder, the raw materials gradually melt and react, while additives are thoroughly blended

- Blowing Agent Injection: Blowing agents such as pentane are precisely injected into the melt using high-accuracy metering pumps

- Dynamic Mixing and Homogenization: Static mixers or specialized screw elements ensure uniform dispersion of the blowing agent, which is effectively encapsulated by the polymer

- Extrusion and Pelletizing: The melt is extruded through a die and cut into unexpanded micropellets in a pressurized underwater pelletizing system, using advanced Ruizhi pelletizing equipment

- Cooling, Dewatering, and Drying: The pellets are rapidly cooled and solidified, then dewatered by centrifugation and dried with hot air to obtain stable expandable polystyrene(EPS) beads

- Screening and Packaging: The product is sieved through a vibrating screening system to ensure uniform particle size before packaging

On-site Production with Ruizhi Machinery’s Older Equipment

What Are the Applications of Expandable Polystyrene (EPS)?

Expandable polystyrene (EPS) is widely used in construction insulation materials and the packaging industry due to its excellent thermal insulation, lightweight structure, and low cost, making it ideal for applications that require both efficiency and easy handling.

Ruizhi Machinery EPS Bead Forming Products